What Are the Differences Between Monocrystalline and Polycrystalline Solar Panels?

Written by qualified solar engineer Leonardo. Last updated:

Page Contents

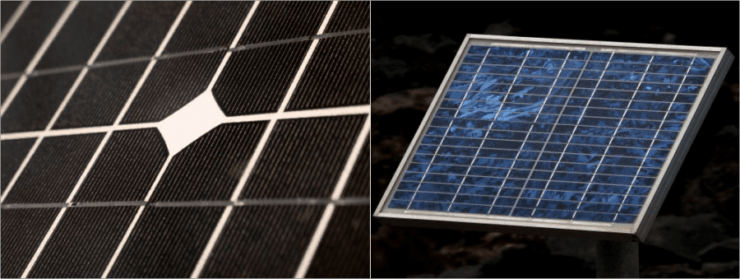

The main differences between monocrystalline and polycrystalline solar panels are their efficiency, color, shape, and material composition. Monocrystalline panels have solar cells made from a single silicon crystal, characterized by their black color and higher efficiency. Polycrystalline panels have cells made from multiple silicon crystals, with a blue color and a slightly lower efficiency.

Thin film solar panels are a less common type. They have a lower price than the two crystalline types, but this is offset by a much lower efficiency. This article will focus on monocrystalline and polycrystalline solar panels.

Before installing a solar power system for your home or business, you must decide which type of solar panel will be used. Polycrystalline panels are the most common, followed by monocrystalline panels. Both types use solar cells made from silicon, but their microscopic structure changes.

Do Monocrystalline and Polycrystalline Solar Panels Have the Same Quality?

Monocrystalline solar panels have a higher efficiency, but this does not mean that polycrystalline panels have a lower quality. The efficiency is determined by the material properties of solar cells, and should not be viewed as an indicator of product quality. If your solar panels are from the top global brands, both monocrystalline and polycrystalline panels are subject to stringent quality standards.

Comparing the two types of solar panels is similar to comparing a sedan with an SUV. High-quality cars of both types are available, but a compact car will have a better gas mileage thanks to its lower weight.

Since high quality is available with both types of solar panels, you can expect an excellent return on investment regardless of the type chosen. The best recommendation is purchasing panels in the Tier 1 list from Bloomberg New Energy Finance: they offer high quality, and they are supplied by companies with a solid financial condition. Having a good product is important, but you should also ensure the manufacturer will be around in the future, in case of a warranty claim. The Tier 1 list includes both monocrystalline and polycrystalline solar panels.

Choosing Between Monocrystalline and Polycrystalline Solar Panels

As mentioned above, quality is not an issue when comparing monocrystalline and polycrystalline panels. Assuming you have an available space that is not covered by shadows, both types will work well. However, monocrystalline solar panels become the best option under the following conditions:

- You have limited space for solar panels.

- Your priority is generating as much electricity as possible.

When space is limited, you cannot make your solar system larger to produce more electricity. The maximum production with the available space is only obtained with the more efficient monocrystalline panels.

Assuming space is not a limitation, you can use any type of solar panel. The best recommendation is getting quotes from multiple solar companies, to find the one that offers the highest return on investment and the quickest payback period.

If you plan to use all your available roof area for solar panels, you will probably have plenty of surplus generation around noon. All the electricity you don’t consume is sent to the power grid, and this may be viable or not depending on how the utility company gives credit. Assuming you fill the roof with solar panels, their surplus production will be higher if they are monocrystalline.

- Some power companies purchase surplus generation from your solar system at the retail price of electricity.

- However, other power companies only give partial credit for every kilowatt-hour sent to the grid by your solar panels.

If the local power company gives full credit for surplus generation, it makes sense to fill your rooftop with monocrystalline panels and maximize production. On the other hand, if you only get partial credit, you can use polycrystalline panels and take advantage of their lower price.

At the end of the month, the balance in your favor is subtracted from the power bill. By producing enough surplus electricity, it may be possible to reduce the power bill to zero. If the balance in your favor exceeds your power bill, the difference is normally carried to the next month. Some electric companies may also even pay you in cash, but this is less common.

Physical Differences Between Monocrystalline and Polycrystalline Solar Panels

Monocrystalline and polycrystalline solar panels differ in both appearance and efficiency. Their manufacturing processes have key differences, which are reflected in the final product.

The materials of a solar panel are the same in both cases: solar cells are made mostly from silicon, with small amounts of other elements. However, the structure of the silicon crystals changes depending on the type of solar panel. Monocrystalline panels have solar cells that are composed of a single silicon crystal, as implied by their name. On the other hand, polycrystalline panels have solar cells that are composed of multiple silicon crystals fused together.

- Monocrystalline panels are more expensive because their manufacturing process is more difficult. Molten silicon must be grown carefully into large crystals called ingots, which are then cut into individual solar cells.

- Polycrystalline panels have a less demanding manufacturing process, since there is no need to grow single crystals from molten silicon. Instead, silicon solidifies into a multi-crystalline block, which is then cut into individual solar cells.

Electric current travels more easily through monocrystalline cells, since they have an ordered crystal structure. On the other hand, polycrystalline cells have divisions in their crystal structure, which cause a slight disruption of electric current. This is exactly why polycrystalline panels have a lower efficiency. However, they are the most popular type because they are easier to produce and more affordable.

Monocrystalline and polycrystalline solar panels also differ in how their solar cells are cut, and this affects the appearance of the finished product. As mentioned above, monocrystalline solar cells are cut from single-crystal silicon ingots. Due to how the ingot is cut, these solar cells have an octagonal shape. On the other hand, the silicon wafers used for polycrystalline cells are made with square molds, and the solar cells have a square shape with straight edges. Polycrystalline solar panels have a lower cost for two main reasons:

- Their manufacturing process is simpler.

- Less silicon is wasted while cutting the wafers into solar cells.

The weight of the solar panel does not change much between the monocrystalline and polycrystalline types. Consider that both panel types use the same material, and what changes is the crystalline structure of silicon.

- The 60-cell panels that are commonly used in home solar systems weigh between 42 and 44 pounds each.

- On the other hand, the larger 72-cell panels weigh between 51 and 53 pounds.

- Therefore, the structural requirements for roofs are the same for both types of solar panels.

The color in solar panels is determined by how sunlight interacts with the solar cell materials. Since polycrystalline panels have solar cells made from multiple silicon crystals, sunlight spreads in multiple directions, causing a blue color and a shiny appearance. On the other hand, monocrystalline solar panels appear black because they absorb sunlight more effectively.

Manufacturer warranties and the expected service life are the same for both solar panel types. Normally, you can expect a 10-year or 12-year warranty against manufacturing defects. There is also a 25-year warranty against the loss of energy production. Solar panel manufacturers guarantee that energy production will not drop below 80% over a 25-year period.

Advantages and Disadvantages of Each Type of Solar Panel

When comparing monocrystalline and polycrystalline panels, it is not possible to say that one type is better than the other. The following table summarizes the advantages and disadvantages of each solar panel type:

Solar Panel Type | Advantages | Disadvantages |

Monocrystalline | -Highest efficiency available -More electricity generation per square foot -The solar power system can be more compact | -Higher price -Their manufacturing process produces more waste |

Polycrystalline | -Lower price than monocrystalline modules -Their manufacturing process produces less waste -Technical support is widely available, since this is the most common type of solar panel | -Lower efficiency than monocrystalline modules -Lower electricity generation per square foot -For a given system capacity, they use more space than monocrystalline modules |

In general, monocrystalline solar panels are a more expensive option to maximize electricity production with the space available. On the other hand, polycrystalline panels offer a more affordable option when space is not a limitation.

Comparing Monocrystalline and Polycrystalline Panels: A Simple Example

If you ask for a specific solar system capacity, such as 10 kilowatts, polycrystalline panels will tend to use more space. Since these panels have lower efficiency, they need to cover more space than monocrystalline panels. However, keep in mind that polycrystalline panels also have a lower cost.

As an example, assume you are comparing the two following solar panel options for a 10-kilowatt installation:

- 275-watt polycrystalline panels, with a retail price of $250 each

- 305-watt monocrystalline panels, with a retail price of $340 each

- Both options have 60 cells, and they have the standard solar panel size of 65” x 39”.

You need 37 of the polycrystalline panels to reach 10 kW of capacity, but you only need 33 of the monocrystalline panels. In other words, you need four additional panels if they are polycrystalline, and the solar system will cover 12 percent more area.

Each solar panel covers around 17.6 square feet. You will cover around 652 square feet with the polycrystalline panels, and around 581 square feet with the monocrystalline panels. However, this is not an issue if you have abundant space. On the other hand, if you only have 600 square feet available, you can only reach 10 kW with the monocrystalline panels.

With the data in this example, the total price of the 37 polycrystalline panels is $9,250. On the other hand, the 33 monocrystalline panels cost $11,220. In this case, one monocrystalline panel is 36% more expensive than one polycrystalline panel. However, reaching 10 kilowatts is only 21% more expensive with monocrystalline modules, since you need less of them.

Keep in mind this is just an example, and solar panel prices vary depending on the model, manufacturer, and project location. In the US you can expect to pay less than $1 per watt if the panels are polycrystalline, and above $1 per watt if they are monocrystalline. Lower prices are possible in large-scale solar systems, such as those in commercial and industrial buildings.

In home solar systems, the cost of solar panels is only around one-third of the total project cost. Consider that panels also need racking for support, as well as inverters, which convert their electricity output into the AC power used by home appliances. A solar power system also requires electrical protection devices, which protect your investment from short circuits and other electrical faults. These costs are similar for monocrystalline and polycrystalline panels.

References

- Photovoltaics -Department of Energy

- Photovoltaics – SEIA

We hope you liked this article. Please rate it or leave us a comment.

Average rating 4.4 / 5. Vote count: 14

No votes so far! Be the first to rate this post.